-

25

-

2025-08-22 10:31:47

Ensuring an electric motor operates reliably hinges on one critical choice: selecting the right carbon brush. The technical properties of carbon brushes vary significantly based on their raw materials and manufacturing processes, making it essential to align brush performance with the specific demands of the motor.

First, the raw materials of carbon brushes directly define their capabilities. Three primary types dominate the market:

- Graphite brushes excel in electrical conductivity and self-lubrication, making them ideal for low-current, low-speed applications such as small power tools and compact electric motors.

- Metal-graphite brushes, reinforced with metal particles, deliver superior conductivity and high-current tolerance, suited for high-speed, high-power equipment like large industrial motors and generators.

- Electrographite brushes, prized for their hardness and wear resistance, thrive in harsh environments, meeting the demands of motors requiring durability and heat resistance.

A key detail often overlooked is the 2-millimeter gap between the brush’s lower edge and the commutator surface. Too little clearance risks damaging the commutator via the brush holder; too much causes excessive brush vibration, leading to breakage.

Signs of a well-performing brush include:

- A long service life without wearing down the commutator or collector ring.

- Stable operation with minimal heat, low noise, secure assembly, and no breakage.

When brushes wear out, full replacement is ideal—mixing old and new brushes can cause uneven current distribution. For large, production-critical units, a phased approach works: replace 20% of brushes per session (20% of each brush holder), with 1–2 week intervals to allow (break-in), ensuring uninterrupted operation.

While uniformity is key—most motors perform best with a single brush type—some large or medium-sized motors with challenging commutation benefit from “dual-brush” setups. The sliding-in side uses a lubricious graphite brush to reduce friction, while the sliding-out side employs a metal-graphite brush for superior spark suppression, optimizing performance.

Uniform pressure across all brushes is non-negotiable to prevent uneven current flow, which can trigger overheating and sparking. Pressure should follow the manufacturer’s “Brush Technical Performance Table,” with adjustments for high-speed or vibration-prone motors (e.g., tractor motors use 0.4–0.6 kgf/cm²).

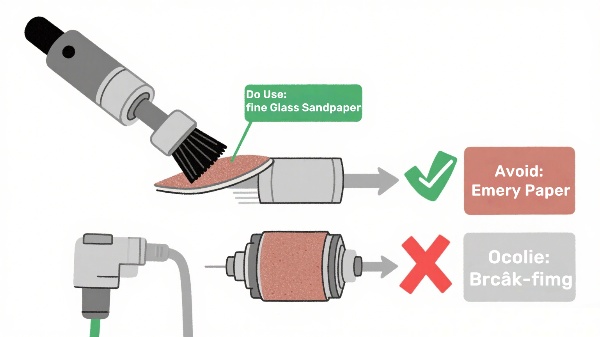

Properly seating new brushes requires arc-grinding directly on the motor:

place fine glass sandpaper between the brush and commutator, then grind along the motor’s rotation under standard spring pressure until the brush’s arc matches the commutator. Avoid emery paper—its abrasive particles can embed in commutator slots, scratching surfaces during operation. After grinding, run the motor at 20–30% load for several hours to form a uniform oxide film, then gradually ramp up to full load. Excessive pressure accelerates wear; insufficient pressure causes unstable contact and mechanical sparking.

Finally, environmental factors matter. High-temperature settings demand electrographite brushes (ordinary graphite degrades quickly under heat). High humidity calls for moisture-resistant brushes to preserve conductivity. Dust or corrosive gases require wear-resistant, corrosion-tolerant options—often metal-graphite brushes.

In short, overlooking carbon brush selection is a costly oversight. Get it right, and your motor runs smoothly; get it wrong, and failure is likely.